Engineering surveying and lofting

(1). Inspection and acceptance of basic engineering. If there are impurities in the foundation, if there are unevenness, they should be repaired and leveled in time. The construction site is clean to ensure the cleanliness of the environment and the quality of construction.

(2). Use a tape measure to measure whether the surrounding facilities meet the standard sports field size, and if it is non-standard, it will be drawn according to the rules of the design drawings, and the measurement and lofting will be performed.

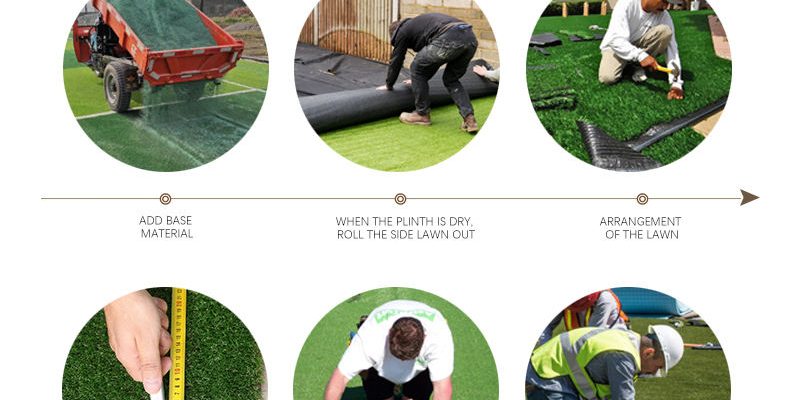

(3). Paving paving

I. Lay non-woven fabrics along the length of the site, the arrangement direction must be 90 degrees with the arrangement direction of the lawn, and the bonding between the non-woven fabrics is firm

II. The line line of the course shall be determined according to the line length specification of the drawing, and the line that has been glued well after self-inspection must be firm and straight.

III.. Lay the lawn on top of the non-woven fabric according to the original specifications, and lap 3-8mm between the lawns.

IV. Cut the lap lawn flat with a cutting knife, and the seam should not be larger than 10mm.

V. Lay the seam cloth under the cutting area, brush the lawn special glue on the joint surface, and the finger touch is dry and the joint is firmly connected and tapped.

Lawn bonding process

Preparation before bonding:

I. The bottom of the lawn, non-woven fabrics, seam fabrics, etc. that need to be bonded are clean and the surface is dry and moisture-free.

II.. The construction environment temperature should be between 0-40 °C for construction, not suitable for construction in rainy and humid weather, otherwise it will lead to poor bonding.

Specific construction steps;

(1). Gluing:

It is required to use a brush to apply a thin and uniform thickness at the bottom of its lawn, and it is not possible to apply glue repeatedly, otherwise it will cause blistering and even falling, strictly control the thickness of the glue, pay attention to the glue speed to be appropriate, and apply them to the two bonded surfaces respectively.

(2). Bonding:

According to the temperature, humidity and other conditions at that time to reasonably control the drying time, generally to apply glue for 10-15 minutes is appropriate, the glue reaches eight or nine percent dry to the hand touch is not sticky. Bonding requires one-time alignment and adhesion. Do not move the bonded object back and forth after bonding.

(3). Pressurization:

After bonding, the surface debris is hammered hard from the bonding place to both sides with a special rubber hammer to make its surface fully bonded and more firm.

(4). Curing:

Its curing time is generally three days, and the final strength of the test is generally ten days. Therefore, it is necessary to pay close attention to its maintenance during the curing period to avoid excessive exposure, water intrusion and movement to achieve the best bonding state.

(5). After bonding, clean the pieces cut in the field before being filled with quartz sand and rubber particles.

Quartz sand paving process

(1). Sand filling process:

The grass seedlings are fixed with special quartz sand to make the grass seedlings not lodging, irrigate the sand to the remaining height of the grass seedlings within 10mm, spread rubber particles on the surface of the grass seedlings, spread evenly, and the grass seedlings shall not be perfused with prismatic sand grains to prevent athletes from being injured.

(2). When spreading, fill it with an artificial zigzag shape.

(3). When the artificial turf field material is indeed paved, quartz sand and rubber particles can be laid.

(4). Quartz sand laying shall be carried out with the concept of integral method.

(5). Quartz sand laying needs to check whether it is flat or reach a certain amount, and the insufficient amount must be added as appropriate.

I. Any debris found during laying must be removed immediately to ensure flatness.

II. After the quartz sand is paved, it is necessary to use a brush with hard bristles to brush back and forth to make the quartz sand fall fully and densely.

III. Rubber granules are paved with the same construction methods and processes.