A couple of decades ago, artificial turf was often a thin carpet atop a hard surface—rough on the knees as well as the eyes. Athletes playing on it complained that it wore their legs out. But as the product improved, so did homeowners’ interest. From the US to the UK, artificial grass retailers have seen sales tick up during pandemic lockdowns, when housebound property owners put their money toward home improvements. Indeed, Google Trends shows a worldwide surge in searches for “artificial grass” during the middle of 2020.

Even the most famous grass enthusiasts like the All England Lawn Tennis & Croquet Club are open to the idea. The organization behind the Wimbledon championship is trialing hybrid court surfaces—real grass weaved with plastic fibers—to promote lawn tennis in climates worldwide and extend the season in the UK.

Still, all of this fake grass sprouting across the planet has sparked backlash. Some of the biggest protests have been in Australia, where synthetic turf installations became more common in home gardens and playing fields during the Millennium Drought—a roughly 12-year dry spell that ended in 2009. Many cities and regions faced extreme water restrictions that included a total ban on lawn watering in some areas.

When today’s artificial grass or sports turf is mentioned, it is often referred to as fake grass, which many athletes associate with the original rough, harsh, and difficult to navigate turf. This outdated technology has given artificial turf a bad name in the sports world; however, so much has changed since the days of fake grass. Technological advances have helped make artificial sports turf easy to switch directions on, cushioned to absorb impacts, and more durable than ever before. Let’s take a look at how artificial sports turf can provide you with a home field advantage.

With the development of the market, artificial grass in the material, process, construction and other aspects have undergone great changes, the purpose of these changes are to make artificial grass in the sports performance closer to natural grass

artificial turf development can be divided into the following stages

The first stage: nylon 6 (polycaprolactam) material is drawn as the main material and inserted in the base cloth. Shaped like a carpet, poor elasticity; Expensive.

The second stage: polypropylene (pp) material, is also after extrusion drawing inserted in the base cloth, paving and filling quartz sand particles, hardness, but the price is cheap.

The third stage: polyethylene (pe) material is the mainstay, but also by extrusion drawing inserted in the base cloth, paving and filling quartz sand, while filling rubber particles, with the elasticity of natural grass, the sports performance is greatly improved;

The fourth stage: to FIFA certification as the standard, pay attention to the foundation, construction and other system engineering construction, this stage in addition to mesh products, but also appeared straight-curved mixing and other products, materials have pe and pp mixing, pe and nylon mixing, sports performance is further strengthened; 、

The fifth stage: monofilament is the mainstay, in addition to the pursuit of sports performance, but also the pursuit of a more ideal appearance, while paying more attention to the construction of the system. ,

The sixth stage: mainly curly grass, a sports and leisure grass specially tailored for noble sports such as gateball court and golf.

Newer Artificial Sports Turf Systems Can Last Over a Decade!

We are a manufacturer.

Please contact us if you have any problems.

| Production method Tufting process | 5/8″,3/4″ gauge |

| Pile fiber Spine shape monofil | 12000dtex |

| Pile height | 60 mm (+ 1 mm) |

| Pile weight | 2950.63gr/m2 (+ 50 gr/m²) |

| Stitches per m¹ | 175 (+ 10) |

| Rows per m¹ | width54 |

| Stitches per m² | + 9720 |

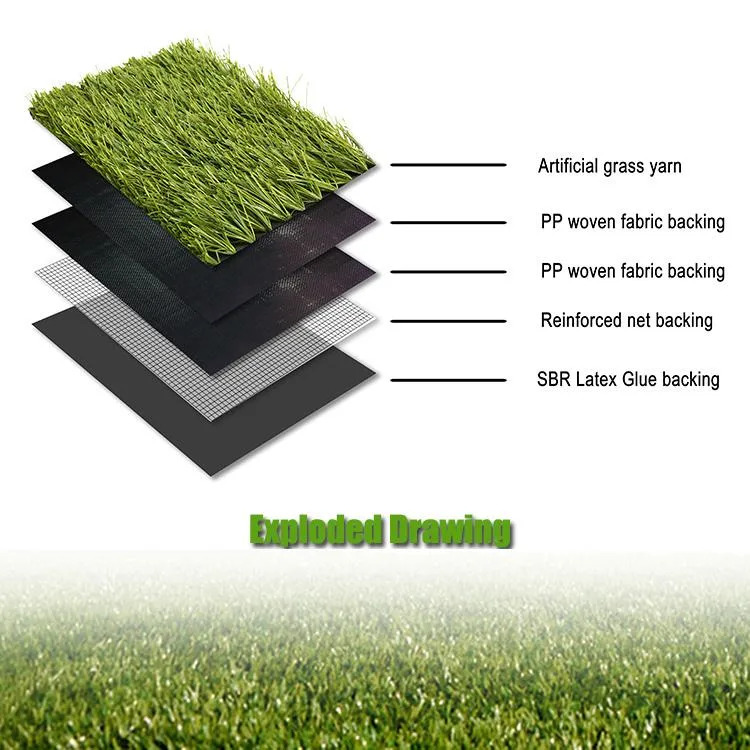

| Primary backing PP backing | colour black, UV stabilized, add with reinforced open cell net backing, colour white, UV stabilized, weight, 300gr/m2 |

| Secondary backing Latex | Latex, 1000gr/m² (+ 100 gr/m²) |

| Total construction weight | 4250.63gr/m2 (+ 100 gr/m²) |

| Color(s) | green |

| Color fastness | Blue scale >=7, Gray scale >=4 |

| Tuft bind | + 40-45 Newton |

| Waterpermeability | + 60 LTR/ m² / min, tested unfilled |

| Roll width | 4 m/2m |

| Loading qty | width 2m/4m 1200m2/20GP, 2800m2/40HQ |

ty Turf is designed for football and consists of diamond shape monofil yarn and durable triple backing. The football system offers you a non infilling football surface, high sports performance and long term durability.

Characteristic:

Characteristic:

.Innovative yarn ensures excellent wear and UV resistance, far exceeding the requirements set by FIFA

.Quality control over every aspect of the project from yarn to manufacture to installation. Products have been used for 51 FIFA accredit football fields.

.Using the high quality raw materials and advanced equipments

.Advanced performance, Excellent wear and Anti-UV, Anti-rust ,Anti-mildew

.Easy maintenance and maintenance

.Could fit for all weather systems

.Environmental friendly,no including heavy metal and toxic substance

. High sports performance, with natural color, looks like natural grass. It is soft and elastic.